Industrial Machine Guide 2025: How to Choose the Right Equipment for Your Production Line

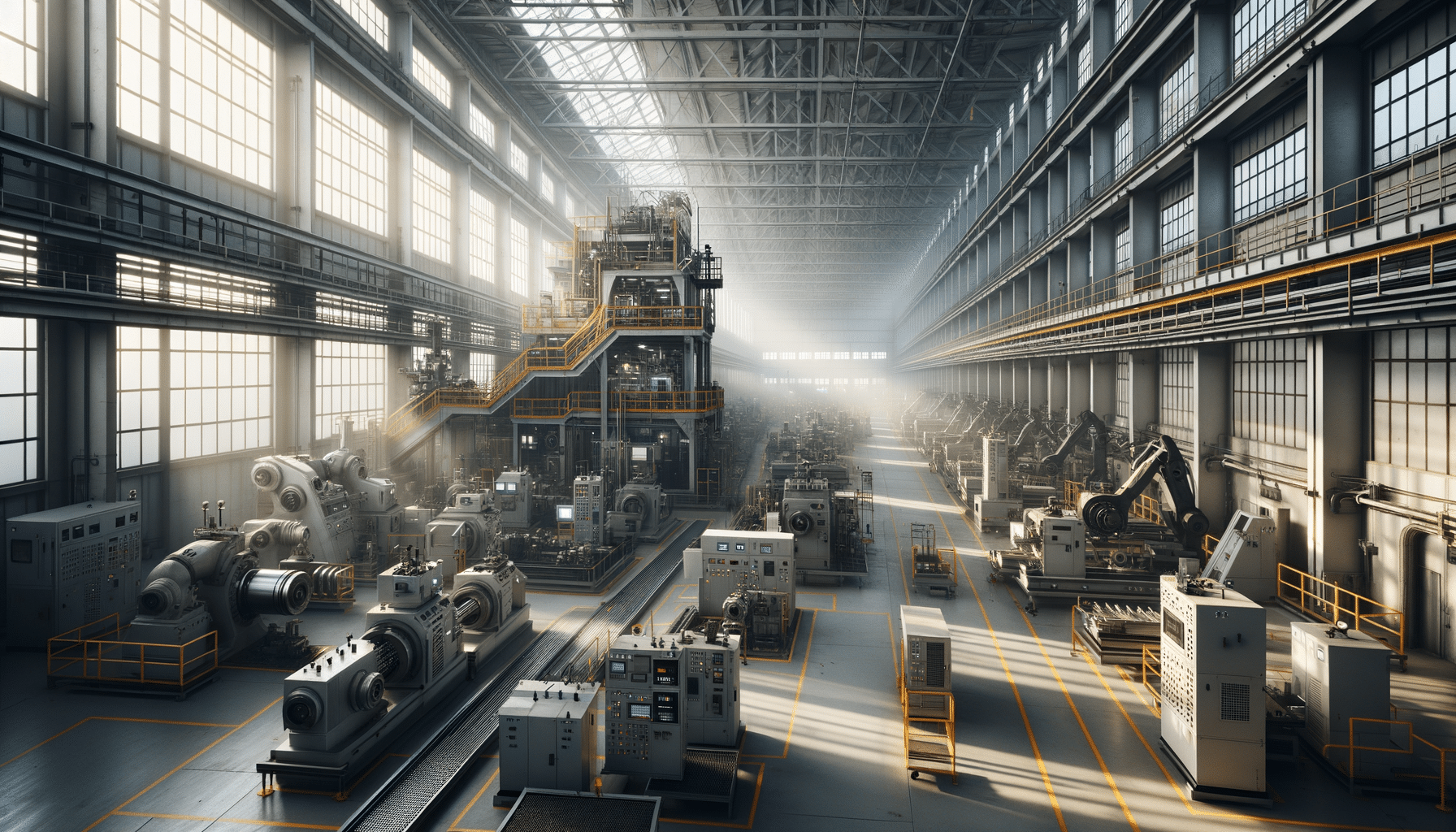

Introduction to Industrial Machines

Industrial machines are the backbone of modern manufacturing processes, playing a pivotal role in enhancing efficiency and productivity. These machines range from simple tools to complex automated systems, each designed to perform specific tasks that streamline operations. As technology advances, the integration of smart systems and automation has become increasingly prevalent, offering manufacturers the ability to optimize their production lines in unparalleled ways.

Investing in the right industrial machinery can significantly impact a company’s bottom line. Efficient machines reduce downtime and operational errors, leading to increased output and consistent quality. This, in turn, boosts customer satisfaction and strengthens the company’s market position. Understanding the different types of machinery and their applications is crucial for businesses looking to innovate and stay competitive in today’s fast-paced industrial landscape.

Types of Industrial Machines

The variety of industrial machines available today is vast, catering to different sectors and applications. Key categories include:

- Material Handling Equipment: These machines, such as conveyors and forklifts, are essential for the movement, storage, and control of materials throughout a facility.

- Machining Tools: Machines like lathes, milling machines, and drill presses are fundamental in shaping and cutting materials to precise specifications.

- Automation Systems: Incorporating robotics and programmable logic controllers (PLCs), these systems enhance precision and reduce human intervention in repetitive tasks.

- Packaging Machines: Essential for the end-of-line process, these machines ensure products are securely packaged and ready for distribution.

Each type of machine serves a specific purpose, and selecting the right one requires a deep understanding of the production process and the desired outcomes. Factors such as production volume, material type, and budget constraints play a crucial role in the decision-making process.

Factors to Consider When Choosing Industrial Machines

Selecting the appropriate industrial machines for your production line involves careful consideration of several factors:

- Production Requirements: Understand the volume and speed of production needed. High-output environments may require more robust and faster machines.

- Space Constraints: Evaluate the available space in your facility to ensure the machines fit comfortably and allow for efficient workflow.

- Cost vs. Benefit: While advanced machines may come with a higher price tag, their efficiency and long-term savings can justify the initial investment.

- Maintenance and Support: Consider the availability of service and support for the machines. Reliable maintenance can prevent costly downtime.

Evaluating these factors helps in making an informed decision that aligns with the company’s operational goals and financial capabilities. Additionally, consulting with industry experts and conducting thorough market research can provide valuable insights into the latest technological advancements and trends.

The Role of Technology in Industrial Machinery

Technology has revolutionized the industrial machinery landscape, introducing innovations that enhance efficiency and precision. Automation and the Internet of Things (IoT) are at the forefront, allowing machines to communicate and operate with minimal human intervention.

Smart machines equipped with sensors can monitor performance in real-time, providing data that helps in predictive maintenance and reducing unexpected breakdowns. Moreover, the integration of artificial intelligence enables machines to learn from data, improving decision-making processes and optimizing operations.

The adoption of these technologies not only increases productivity but also ensures higher quality standards. By leveraging technology, manufacturers can achieve greater flexibility and adaptability in their production lines, meeting the ever-changing demands of the market.

Conclusion: Maximizing Efficiency with the Right Industrial Machines

In conclusion, choosing the right industrial machines is a critical decision that can significantly influence the efficiency and success of a production line. By understanding the various types of machinery and considering key factors such as production requirements, space, and technology integration, manufacturers can make informed choices that enhance their operational capabilities.

The future of industrial machinery is bright, with continuous advancements promising even greater efficiencies and innovations. Staying informed about these developments and adapting to new technologies will be essential for businesses aiming to maintain a competitive edge in the global market.